YIZHE ZHU

PORTFOLIO

ASSEMBLAGE

(Final degree project)

CONTEXT

In modern society, people live in a stable space and face a constant environment. We are always in the same places doing the same things every day. When we spend too much time in this situation, it can make our life progressively dull, thus affecting our mental health. Most people do not want to be confined to limited space, so the desire to travel the world arises. It's especially true in times of the pandemic. At the beginning of the confinement, many people chose to leave the city and go to less populated areas where is more space to move around, precisely because of the sense of freedom.

Half of the people would travel to more natural places to maintain a distance from human society. But the lack of primary living conditions means that most people do not have the opportunity to visit the destinations they wish to go to. Above all, there is a lack of habitable space.

CAPSULE

Assemblage is a cylindrical capsule made up of modular and prefabricated pieces. This capsule has a system that allows users to assemble their space in their way. Visually the shape of the house integrates a lot with nature, like trees, which have cylindrical trunks too. This capsule is built with four curved walls, a floor and a ceiling: the wall with a door, the wall divided into three parts a window, the complete wall, the ceiling and the floor, which are circular. These pieces created a cylindrical capsule of 3m in diameter and 2.20m in height, containing an area of 7m2.

CONSTRUCTION

I proposed to apply joints as the connections to join the pieces to facilitate the manufacture and assembly process of the house. Each wall piece has a raised mould on one side and a concave mould on the other side, and two rails above and below to join the ceiling and the floor with the walls. This system allows the house to be assembled and disassembled easily and also increases the flexibility of customising the space, as the positions between the pieces are interchangeable. The edges of the parts are fitted with rubber strips to ensure air and water tightness. It is not so easy to install these joints. Therefore, I choose 3D printing as the technique to manufacture these parts, which has high precision. The material used is polyester reinforced with fibreglass, which is very easy to mould with 3D printing. It is a strong, lightweight, waterproof and thermal insulation material.

I proposed to apply joints as the connections to join the pieces to facilitate the manufacture and assembly process of the house. Each wall piece has a raised mould on one side and a concave mould on the other side, and two rails above and below to join the ceiling and the floor with the walls. This system allows the house to be assembled and disassembled easily and also increases the flexibility of customising the space, as the positions between the pieces are interchangeable. The edges of the parts are fitted with rubber strips to ensure air and water tightness. It is not so easy to install these joints. Therefore, I choose 3D printing as the technique to manufacture these parts, which has high precision. The material used is polyester reinforced with fibreglass, which is very easy to mould with 3D printing. It is a strong, lightweight, waterproof and thermal insulation material.

A battery-controlled solar panel is installed on the top dome of the capsule to generate electricity. The dome's rim has a bowl shape which functions to collect rainwater. The water will flow into the tanks and supplies to the capsule through the piping embedded inside the wall. We try to use renewable resources to be as sustainable and environmentally friendly as possible.

CONNEXION

Each capsule room has only its function and can be used as one of the essential functional areas such as the bathroom, kitchen, bedroom and living room. The user can therefore build the necessary house to suit the habitant's needs.

To ensure unobstructed access to the various rooms, I proposed to create passages between each functional area. The connexion in this solution consists of several platforms of different heights. This approach allows the building to adapt to the form of the terrain and also reduces the impact on the environment.

PLANS

RENDERS

V-ray production

DISTRIBUTION

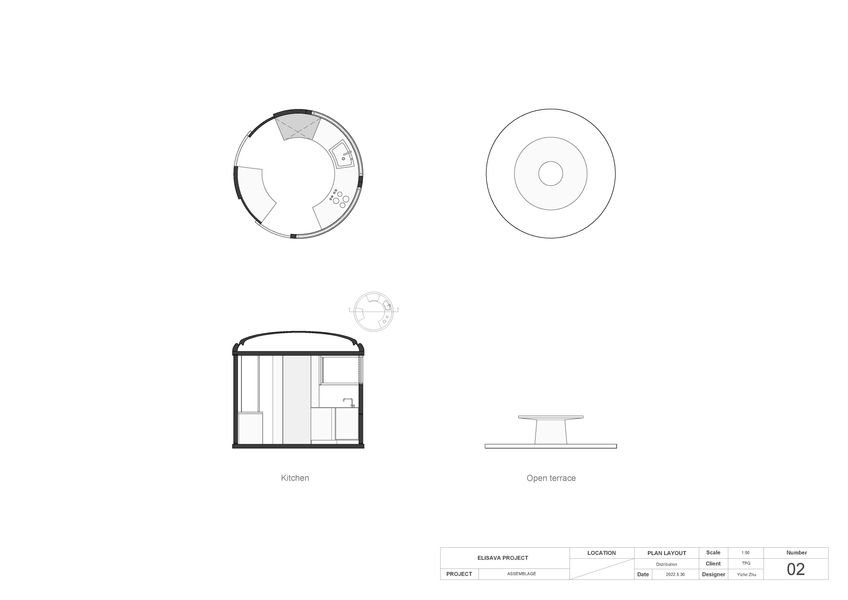

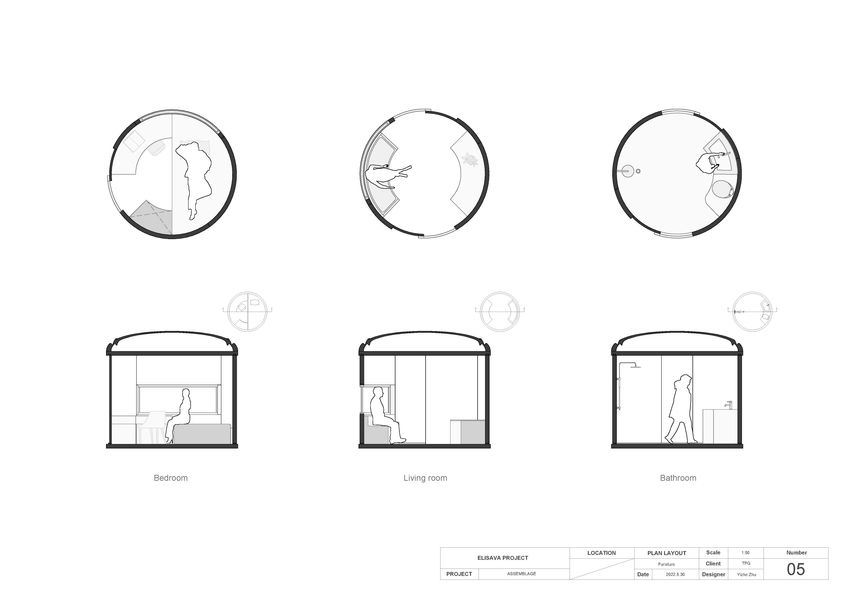

The inside organisation offers four typologies, the bedroom, the living room, the bathroom, and the kitchen, which are the four most essential functional zones of living space. The design and layout of the furniture are based on a template, which divides space into three parts towards the centre of the inner circle, and then a straight line cuts the interior space every 45 degrees. All furniture will be placed against the wall. This centrifugal distribution fits the capsule shape and creates modular furniture, making the inside organisation much more flexible.

All the capsules contain the basics of daily life. The bedroom accommodates a desk, a bed that takes up half of the space, and a wardrobe. In the living room, there is a sofa and a low table. The shower takes up the whole bathroom and includes a sink and a toilet. The kitchen has a fridge, a small table and a worktop with an integrated sink and induction. And last but not least, there is an open terrace, where you can sit and get some fresh air after all the purpose of living here is to enjoy nature. The modular furniture allows residents to arrange the furniture placement according to their preferences.

PLANS

RENDERS

V-ray production

MODELS